|

Industrial and Manufacturing Engineering Southern Illinois University Edwardsville |

|

Research |

|

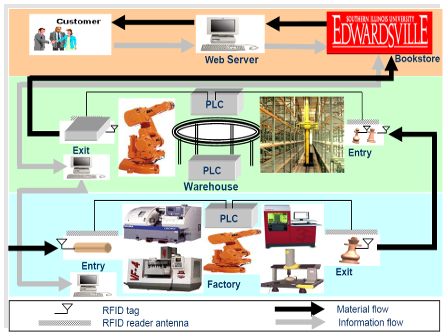

NSF MRI: Acquisition of Major Components Required for Constructing Supply Chain Test-bed

The objective of this award from the Major Research Instrumentation program is to develop a unique, multi-disciplinary and state-of-the-art supply chain test-bed in the School of Engineering at Southern Illinois University Edwardsville (SIUE). This test-bed will provide faculty, technical experts and students with valuable resources necessary to develop solutions to manufacturing and supply chain problems. Specifically, the test-bed will be constructed in a way to represent various layers of supply chains such as suppliers, manufacturing facility, warehouses, and customer locations. Importantly, the test-bed will be designed in a generic manner to allow further technological advancements. It can also be configured to explore the impact of lean production in supply chain systems. The test-bed will be built in a real-life setting and SIUE Bookstore will be a primary retailer. A Web-server system will be used to enable online control and integration of information, production, and cash flows. |

|

|

|

Intuitive Surgical 2011 Robotics Research Grant: Ergonomic analysis of robotic surgery

Objectives of this project is (i) to quantify the ergonomic advantage of the da Vinci Surgical System over conventional laparoscopic surgery as measured by electromyography (EMG) and NASA Task Load Index scores, and (ii) to determine the effect of surgical experience on the potential ergonomic benefit of robotic surgery. Drs. Awad (Washington University) and Cho (SIUE) expect this project would show ergonomic benefit of robotic surgery over traditional laparoscopy to surgeons.

|

|

|

|

STEP Research Grant: The use of electronic nose for on-line and real-time tool condition monitoring systems

Optimal performance of machining processes relies on the availability of information about process conditions and feedback to the process controller. The condition of the cutting tool is the most crucial and determining factor for machine tool automation, hence online tool condition monitoring is of great interest to both academia and industry. A new paradigm for on-line and real-time tool condition monitoring has been recently undertaken in the School of Engineering at Southern Illinois University Edwardsville (SIUE) by the PIs of this project. The goal of this research is to test a hypothesis, “Gas detection sensor (or electronic nose), when combined with data mining methods, is effective in detecting tool wear in machining processes such as milling and turning operations.” Our novel idea is to design and test new tool inserts that have chemical compound inclusions in their substrate to significantly enhance the sensitivity of an electronic nose (e-Nose) for tool condition monitoring. We envision that by doping chemical compounds in tool insert substrates, the sensitivity of detecting various tool conditions will increase dramatically.

|

|

|